Rammed Earth is well known in our

countries since a very long time. It was used

for building outside fences or in small

houses. In this method, a layer of soil is put

on each other inside a wooden frame and

is rammed with a wooden rammer.

This method has been improved greatly in

Europe and Latin America by using different

rammers, such as the Pneumatic Rammers

and the Vibration Plates. It’s very successful

in big projects due to its low cost and

durability.

The soil suitable for Rammed Earth:

It is very important that the soil used in

Rammed Earth consists of the following

ingredients/ percentages:

– Gravel & Sand: 50-70 %

– Silt: 15-30 %

– Clay: 10-20 %

A soil lab analysis can give us the exact

percentages of the soil ingredients and it is

essential when using this method in big

projects. A simple test can be also applied

(the cigarette method)

The cigarette method:

1. Mix Soil with water to form a thin tube,

its diameter 2 cm and length 20 cm.

2. We put this tube at the edge of a table

and we push it outside and watch the

length of the broken part of this tube.

3. If the length of the broken part is 8-12cm,

this means that the soil consists of the

above percentages and is suitable for

building.

4. If the length of the broken part is less

than 8cm, this means that the soil

consists of high percentage of sand.

5. If the length of the broken part is more

than 12cm, this means that the soil

consists of high percentage of clay.

Specifications of the Frames used in

Rammed Earth:

1. When building with Rammed Earth, we

need durable frames to bear the soil

pressure especially when using the

Pneumatic Rammers.

2. The frames should be light in weight and

easy in handling, fixing and un-fixing to

be able to use it several times.

3. Frame measures:

– Length: 1.50 – 3.00 m

– Height: 0.50 – 1.00 m

– Width: should be wide enough to

enable the mason to stand inside

it to ram the earth.

Ramming:

Foundation: Should be built with red bricks

or natural stones with cement with 30-60 cm

height above the earth level. A layer of

insulation course should be fixed before

starting building with Rammed Earth.

• Soil to be rammed in the wooden frame

in layers of 10cm each.

• It is preferable to ram the soil from

outside to inside the frame.

The edges of the walls should not be sharp

to avoid its quick damage.

Rammers:

There are different kinds of rammers:

1. Manual Rammers: It is a wooden rod

with a heavy metal head. This metal

head can be in circular or square shape

to facilitate this process.

2. Pneumatic Rammers: It works with air

compressors and produce high impact

of frequencies, which help the soil to be

rammed properly and quickly. There are

different kinds of these rammers and

choosing them depends on the project

size.

3. Vibration Plate: This rammer was

improved in Germany by using an

electric motor that wi ll cause an

automatic switch to move back and forth

in the wooden frame and thus ram the

earth without any manual interference.

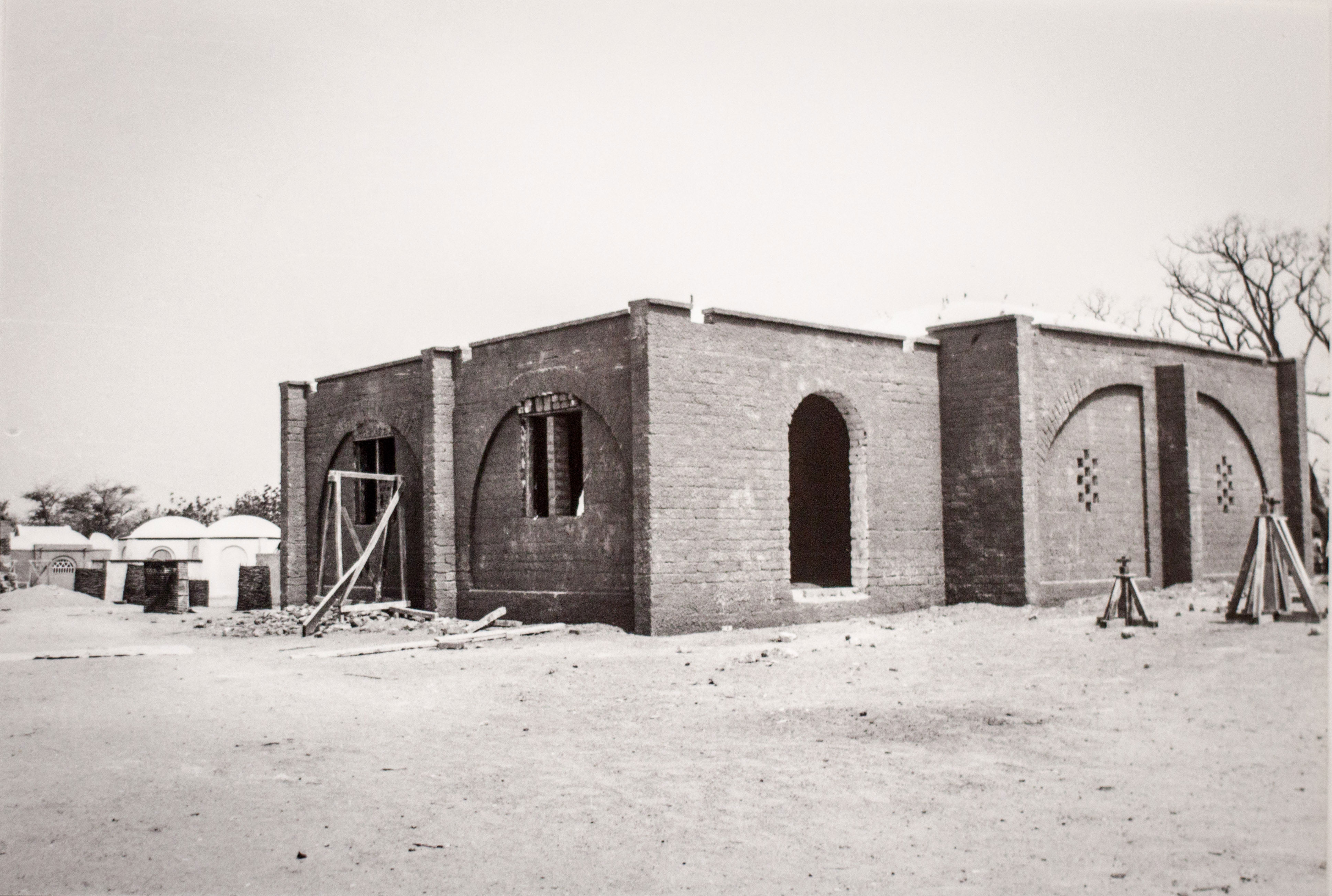

In Egypt, we implemented Rammed Earth

successfully. Dome and vault were

roofed on the Rammed Earth walls. The

outcome was very beautiful and

harmonic. People and masons admired

that combination. I will not forget when

the masons looked at the Rammed Earth

walls with its structure of layers of Gravel

and Clay, and they said: “It looks like a

mountain, 2000 years old“!

The success of this stage is due to the

support of my dear friend Martin Rauch

from Austria and I’m deeply grateful and

debited to him