In the summer of 1991, I visited the farm in the desert and was received by a strong sand storm along with the sunny hot weather. For me, that was a very hard and new experience facing the real desert nature.

After several field visit, we agreed with the landowner on the following program :

- Planning and constructing a water pump station.

- Planning and constructing a warehouse.

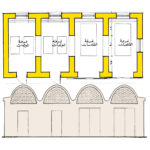

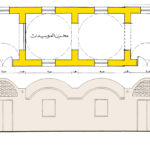

- Planning and constructing a rest house for the engineers and staff with a small mosque.

In the meantime the agricultural group was analyzing the desert soil.

The main concepts of the design is to solve the following problems:

- The hard climate conditions during the winter and summer seasons.

- The shortage of building materials.

- The lack of professional labor and masons.

We started to look for available natural local materials in the area. Finally, we could find a quarry which could provide us with the required quantities of natural calk stones blocks.

During our investigations in the area, we met an old Bedouin who told us that we could find “Black Earth” in the desert as the area was a cultivated land in the past.

We took a sample from that soil and carried out several trails. When we used it as a mortar with calk stones blocks. The trial failed because the soil couldn’t bend as a mortar with those blocks. The next trial was using that soil as mortar with the tafla (clay) red bricks. The trial succeeded ad accordingly we decided to use the following building materials:

- Foundation: Natural Calk stones blocks with cement as a mortar.

- Walls: Tafla (clay) red bricks with the black soil as a mortar. Walls were built with 50 cm thickness.

- Domes and vaults: Tafla (clay) red bricks with the black soil as a mortar.

The first part of the project was designed the “Water Pump Station”. Roofing th station was by several vaults.

On discussing the design with the responsible engineer, he proclaimed that the strong continuous machines vibrations would destroy the walls and the vaults. I then changed the design to face that problem. In the design I built a special foundation to fix the machines on it and isolated that foundation to eliminate and isolate the vibrations from reaching the walls.

To overcome the hot temperature inside the station, each vault had two openings facing each other, one opening was smaller than the other one. The small opening, facing the wind direction, would let the wind enter that station and expel the inner hot air from the other bigger opening.

The landowner being interested and impressed by the traditional style, invited all the engineers in his company to attend my design presentation. I had the feeling that no one in that meeting believed that the Pump station would function, except Mr. Barakat, The landowner.

The second step was preparing the group of masons who could work patiently and efficiently in that isolated hot site. I tried to hire the Lake Karoon trained masons, but they refused to work in that difficult weather. Tharwat, my brother, arranged a group of professional masons from Aswan who were acquainted with that climate.

The construction of the pump station was completed in 23 days. Then the masons decided to leave the site to go back home.

For the construction of the rest of the project, we arranged for another group of professional masons from Aswan. Tharwat my brother and myself lived in the site to work closely with the new group of masons and that human touch facilitated our job.

After completing the whole construction, the landowner invited his employees, engineers and relatives to see the successful new accomplishment.

After three years, this project is a landmark among the rest of the farms in the areas.